From operator panels and visualization software for machine-level human machine interface functionality right up to scalable SCADA systems for the most diverse requirements in process visualization:

SIMATIC HMI offers a finely graded range of innovative and cost effective products and systems from a single source.

From operator panels and visualization software for machine-level human machine interface functionality right up to scalable SCADA systems for the most diverse requirements in process visualization:

SIMATIC HMI offers a finely graded range of innovative and cost effective products and systems from a single source.

A finely graded range of HMI devices is available for local operator control and monitoring: From Key Panels and Basic Panels to Comfort Panels and Mobile Panels. With IP65/NEMA 4 degree of protection at the front, high EMC and extreme vibration resistance, the SIMATIC HMI operator panels are ideally suited for use at machine level in rough industrial environments. Thanks to their compact design with a shallow mounting depth, the stationary HMI devices can be fitted anywhere, even where only restricted space is available.

The SIMATIC HMI Panels facilitate innovative operator control and monitoring combined with ruggedness, stability and simplicity. On the Comfort Panels in particular, standard hardware and software interfaces, e.g. the Multimedia Card/SD Card, USB, Ethernet, PROFIBUS DP, Visual Basic scripts or customer-specific ActiveX controls, provide more flexibility and openness as well as access to the office world.

One configuration software for everything

Siemens provides the complete modular system of matched components for automation solutions from one source and - with Totally Integrated Automation - one of the most globally successful automation concepts. SIMATIC WinCC (TIA Portal) is an integral component of this world. It offers crucial advantages. Thanks to the triple uniformity in configuration/programming, data management and communication, automation solution engineering costs are significantly reduced.

SIMATIC WinCC (TIA Portal) is a tool for the uniform configuration of all SIMATIC HMI Panels as well as PC-based systems. Graded variants are available for every task. The software permits simple and efficient configuration. Programming experience is not required.

Once created, configurations can be reused within the family.

Despite being consistently incorporated into the SIMATIC world, the Panels are nevertheless open for connection to PLCs from many different vendors. The standard delivery includes a comprehensive range of user-friendly drivers.

A finely graded range of HMI devices is available for local operator control and monitoring: From Key Panels and Basic Panels to Comfort Panels and Mobile Panels. With IP65/NEMA 4 degree of protection at the front, high EMC and extreme vibration resistance, the SIMATIC HMI operator panels are ideally suited for use at machine level in rough industrial environments. Thanks to their compact design with a shallow mounting depth, the stationary HMI devices can be fitted anywhere, even where only restricted space is available.

The SIMATIC HMI Panels facilitate innovative operator control and monitoring combined with ruggedness, stability and simplicity. On the Comfort Panels in particular, standard hardware and software interfaces, e.g. the Multimedia Card/SD Card, USB, Ethernet, PROFIBUS DP, Visual Basic scripts or customer-specific ActiveX controls, provide more flexibility and openness as well as access to the office world.

One configuration software for everything

Siemens provides the complete modular system of matched components for automation solutions from one source and - with Totally Integrated Automation - one of the most globally successful automation concepts. SIMATIC WinCC (TIA Portal) is an integral component of this world. It offers crucial advantages. Thanks to the triple uniformity in configuration/programming, data management and communication, automation solution engineering costs are significantly reduced.

SIMATIC WinCC (TIA Portal) is a tool for the uniform configuration of all SIMATIC HMI Panels as well as PC-based systems. Graded variants are available for every task. The software permits simple and efficient configuration. Programming experience is not required.

Once created, configurations can be reused within the family.

Despite being consistently incorporated into the SIMATIC world, the Panels are nevertheless open for connection to PLCs from many different vendors. The standard delivery includes a comprehensive range of user-friendly drivers.

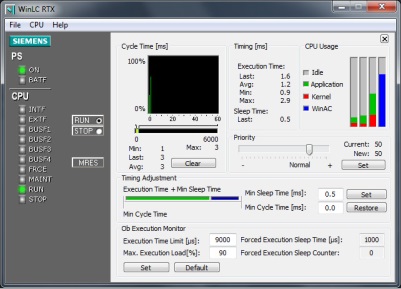

WinCC flexible is ideal for use as the HMI software in all applications in which operator control and monitoring is required on site - whether in production and process automation.

WinCC flexible is designed on a non-industry specific basis and it offers Engineering Software for SIMATIC HMI operator control and monitoring devices from the smallest Micro Panel up to PCs as well as Runtime Visualization Software for single-user solutions under Windows 2000 / XP.

In this connection, you can transfer projects to different HMI platforms and run them there without needing to convert the projects.

Connectivity to SIMATIC S7 via PPI, MPI, PROFIBUS-DP and Industrial Ethernet, plus multi-protocol drivers for controllers made by leading manufacturers and manufacturer-independent communication via OPC ensure that you always have the right connection for a wide variety of automation solutions.

The multilingual engineering software that you can switch at the push of a button; the option of creating projects with up to 32 languages at the same time - 16 (depending on employed device) of which you can switch online are excellent reasons for using WinCC flexible on a worldwide basis. Web-based service concepts that exporting OEMs and large multinational companies can utilize to promote their business globally.

Using the WinCC flexible/Sm@rtAccess option operator stations have access to each others' tags and screens. This yields innovative TCP/IP communication-based concepts for the HMI and automation tasks that you have to solve

- Operator stations with cross-plant access to current process values and screens

- Distributed operator stations for operating large, physically distributed machines

- Local control room solutions with options for central archiving, analysis and further-processing of process data

- Link to Office applications

The WinCC flexible/Sm@rtService option offers the functionality for innovative service concepts:

- Event-driven sending of e-mail and text messages to the service staff

- Remote control of on-site stations across the Intranet/Internet

- Diagnosing operator stations using ready-made diagnostic functions and screens

- Service and maintenance functions (downloading projects, downloading/uploading recipes).

WinCC flexible is ideal for use as the HMI software in all applications in which operator control and monitoring is required on site - whether in production and process automation.

WinCC flexible is designed on a non-industry specific basis and it offers Engineering Software for SIMATIC HMI operator control and monitoring devices from the smallest Micro Panel up to PCs as well as Runtime Visualization Software for single-user solutions under Windows 2000 / XP.

In this connection, you can transfer projects to different HMI platforms and run them there without needing to convert the projects.

Connectivity to SIMATIC S7 via PPI, MPI, PROFIBUS-DP and Industrial Ethernet, plus multi-protocol drivers for controllers made by leading manufacturers and manufacturer-independent communication via OPC ensure that you always have the right connection for a wide variety of automation solutions.

The multilingual engineering software that you can switch at the push of a button; the option of creating projects with up to 32 languages at the same time - 16 (depending on employed device) of which you can switch online are excellent reasons for using WinCC flexible on a worldwide basis. Web-based service concepts that exporting OEMs and large multinational companies can utilize to promote their business globally.

Using the WinCC flexible/Sm@rtAccess option operator stations have access to each others' tags and screens. This yields innovative TCP/IP communication-based concepts for the HMI and automation tasks that you have to solve

- Operator stations with cross-plant access to current process values and screens

- Distributed operator stations for operating large, physically distributed machines

- Local control room solutions with options for central archiving, analysis and further-processing of process data

- Link to Office applications

The WinCC flexible/Sm@rtService option offers the functionality for innovative service concepts:

- Event-driven sending of e-mail and text messages to the service staff

- Remote control of on-site stations across the Intranet/Internet

- Diagnosing operator stations using ready-made diagnostic functions and screens

- Service and maintenance functions (downloading projects, downloading/uploading recipes).

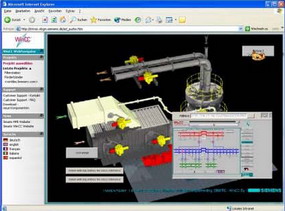

WinCC is designed on a non technology-and industry-specific basis, it is modular and you can extend it in a flexible way; WinCC makes possible both demanding single-user applications in mechanical engineering as well as complex multi-user solutions or even distributed systems including several servers and clients - also internet-based - in plant visualization .

WinCC combines both production and process automation - numerous references across any number of applications and branches of industry prove this.

WinCC has established as an industry standard in the field of process visualization, no matter if you look at it as an autonomous SCADA-System (Supervisory Control and Data Acquisition) or the HMI component of Control systems like SIMATIC PCS 7 or Spectrum Power CC for energy management.

A large number of WinCC Options and Add-ons allow industry-specific solution, e.g. in pharmaceutical industry or water treatment applications.

The scope of supply of WinCC includes all the most important communication channels for linking to SIMATIC controllers( S7, S5, 505 e.g. via the S7 Protocol Suite ), as well as non-proprietary channels like PROFIBUS-DP/FMS, DDE (Dynamic Data Exchange) and OPC (OLE for Process Control); you can get other communication channels as Add-ons. Since all controller manufacturers provide appropriate OPC servers for their hardware, there are virtually no limits to what you can connect to WinCC.

SIMATIC WinCC integrates a powerful, scaleable Historian based on Microsoft's SQL Server 2000 in the basic system to be used as a central information exchange in the form of a cross-company Historian server. Different clients for evaluation, open interfaces (Open database- and programming interfaces) and various options for IT and business integration are the basis for Plant Intelligence. In particular, this makes it possible to link to the production and company management levels (MES and ERP).

WinCC is designed on a non technology-and industry-specific basis, it is modular and you can extend it in a flexible way; WinCC makes possible both demanding single-user applications in mechanical engineering as well as complex multi-user solutions or even distributed systems including several servers and clients - also internet-based - in plant visualization .

WinCC combines both production and process automation - numerous references across any number of applications and branches of industry prove this.

WinCC has established as an industry standard in the field of process visualization, no matter if you look at it as an autonomous SCADA-System (Supervisory Control and Data Acquisition) or the HMI component of Control systems like SIMATIC PCS 7 or Spectrum Power CC for energy management.

A large number of WinCC Options and Add-ons allow industry-specific solution, e.g. in pharmaceutical industry or water treatment applications.

The scope of supply of WinCC includes all the most important communication channels for linking to SIMATIC controllers( S7, S5, 505 e.g. via the S7 Protocol Suite ), as well as non-proprietary channels like PROFIBUS-DP/FMS, DDE (Dynamic Data Exchange) and OPC (OLE for Process Control); you can get other communication channels as Add-ons. Since all controller manufacturers provide appropriate OPC servers for their hardware, there are virtually no limits to what you can connect to WinCC.

SIMATIC WinCC integrates a powerful, scaleable Historian based on Microsoft's SQL Server 2000 in the basic system to be used as a central information exchange in the form of a cross-company Historian server. Different clients for evaluation, open interfaces (Open database- and programming interfaces) and various options for IT and business integration are the basis for Plant Intelligence. In particular, this makes it possible to link to the production and company management levels (MES and ERP).

Baouchrieh - Metn

2616 5311 Lebanon

P.O.BOX 11-0242 Riad El Solh-Beirut

1107 2020 Lebanon

Beirut, Lebanon

SOCIAL

WITH US !